Application of Acoustic Imaging Online Monitoring in 10kV High and Low Voltage Distribution Rooms

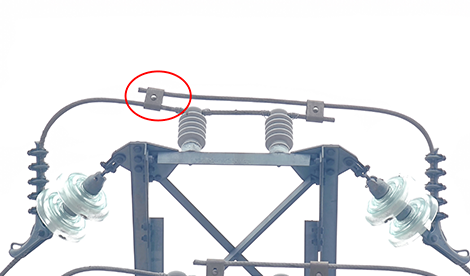

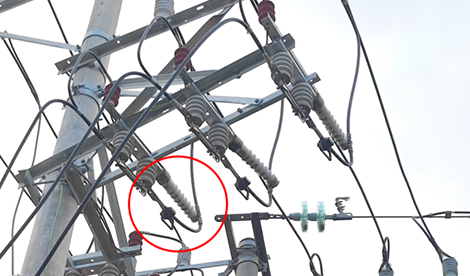

The user installed an acoustic imaging online monitoring system in the high and low voltage distribution room, and found obvious positioning points in the 10kV switchgear busbar room using the acoustic imaging online monitoring device.